Consigue una cotización

Highlights of New Packaging Innovations

For 17 years, The Packaging Conference has been a beacon for unveiling new trends and technologies in packaging, with a notable inclination towards plastics — the most prominent and evolving segment in packaging materials. The latest conference, held from February 12-14 in Austin, Texas, lived up to its reputation by showcasing cutting-edge developments.

The theme of change is a constant at The Packaging Conference, adapting with each year to spotlight the most pressing issues in the industry. This time, the spotlight is on sustainability. The focus is intense on minimizing the environmental impact of packaging and enhancing recyclability. This theme is timely, as the industry faces the challenge of navigating new extended producer responsibility (EPR) laws, affecting both material producers and brand owners.

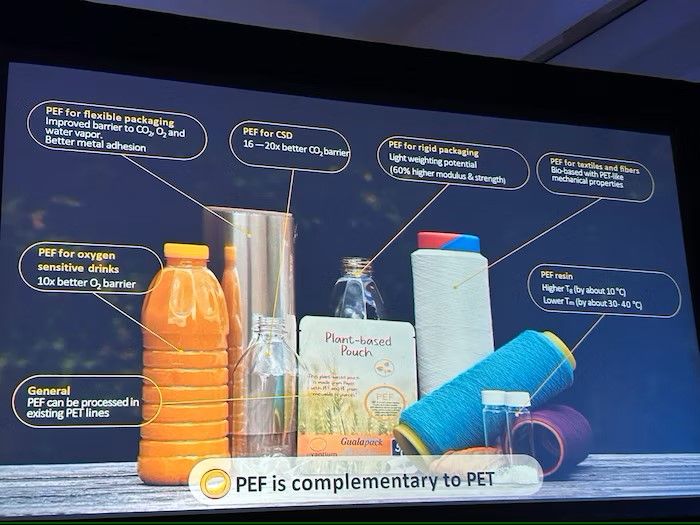

At the recent Packaging Conference, several innovative approaches to packaging were presented, showcasing both emerging and well-established technologies. One standout discussion came from Bineke Posthumus, the Director of Business Development at Avantium. She introduced the audience to a revolutionary development in packaging materials: 100% plant-based PEF (polyethylene furanoate). This biopolymer, derived from first-generation agricultural crops, presents a sustainable alternative to PET plastics.

PEF is not just a biopolymer but a "drop-in" solution, seamlessly integrating into current manufacturing processes and recyclable systems. Its advantages over PET include better barrier properties, which can extend the shelf life of products. Importantly, Posthumus highlighted that PEF is poised to be cost-competitive with traditional fossil-based materials once produced at scale. With a carbon footprint 60% lower than virgin PET, as shown in a life-cycle assessment (LCA), Avantium’s PEF technology marks a significant step towards decarbonizing everyday products. Avantium is on the verge of completing a plant capable of producing 5 kilotons of PEF annually, with ambitious plans for a future facility designed to produce over 250 kilotons per year.

At The Packaging Conference, Daniel Abramowicz, the soon-to-retire Executive Vice President of Technology & Regulatory Affairs at Crown Holdings, introduced an advancement in aluminum can decoration: the Velox DTS (direct-to-shape) digital printing technology. Developed collaboratively by Velox with support from Crown, this technology marks a significant leap from the traditional method of using shrink-sleeve labels for short production runs, which often complicates the recycling process.

The Velox DTS (direct-to-shape) digital printing technology, spotlighted by Daniel Abramowicz from Crown Holdings, introduces a breakthrough for cost-effective, short-run printing on aluminum cans. This innovative system, boasting an oval configuration, ensures continuous motion of cans under the printheads, achieving impressive speeds of up to 500 cans per minute. Capable of decorating cans in six to eight colors, Velox DTS also offers the capability to produce both matte and tactile finishes, adding a new dimension to can design. Abramowicz announced the commercial rollout of this technology, with 12 systems set to be implemented across North America, marking a significant milestone in packaging printing technology.

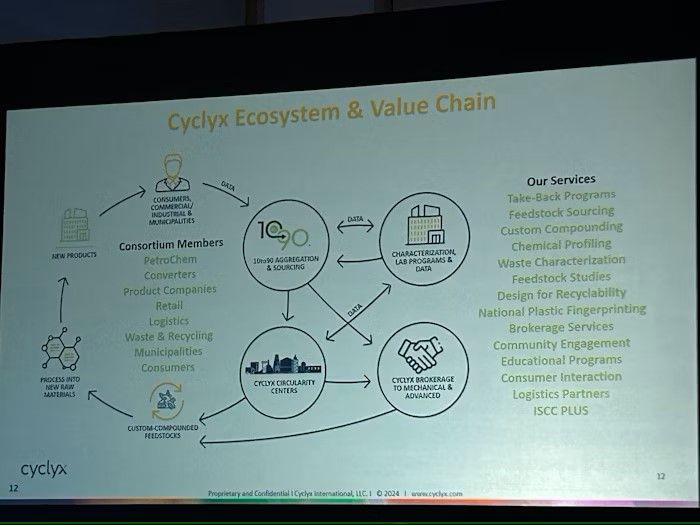

Bill Cooper, the Senior Vice President of Corporate Strategy & Development at Cyclyx, presented an ambitious plan to transform the landscape of single-use packaging recycling during The Packaging Conference. Cyclyx's 10to90 vision aims to elevate the use of recycled plastics from a mere 10% to an impressive 90%. As a consortium of 45 members spanning the entire plastic value chain, Cyclyx focuses on innovative feedstock management to achieve this goal. The company intends to harness its network, including Material Recovery Facilities (MRFs), to gather all types of plastics. By distinguishing plastics based on their chemical composition for recycling — rather than the traditional method of sorting by polymer type — Cyclyx targets a more efficient approach to separating materials suitable for mechanical recycling from those fit for chemical recycling. Cooper's explanation sheds light on the complex yet critical process necessary to significantly enhance recycling rates and sustainability in the packaging industry.

Bill Cooper, Senior Vice President of Corporate Strategy & Development at Cyclyx, shared the company's bold "10to90" vision during a discussion on the future of single-use packaging. Cyclyx, a consortium of 45 members spanning the plastic value chain, aims to revolutionize plastic recycling by increasing the current rate from 10% to an ambitious 90%. The company focuses on managing feedstock for recycling, collaborating with partners like Material Recovery Facilities (MRFs) to collect all types of plastics. Their strategy involves a detailed sorting process that prioritizes chemical composition over polymer types, paving the way for more efficient recycling methods.

Once the plastics are sorted, Cyclyx prepares the feedstock for chemical recycling processes, distributing it to recyclers. Cooper outlined that of the collected plastics, one-third would be directed towards mechanical recycling, while the remaining two-thirds would benefit from advanced recycling techniques. Cyclyx is currently testing this innovative system in Houston and has announced plans for a groundbreaking $100 million Cyclyx Circularity Center in the city. This facility is set to be a significant step forward in recycling infrastructure, focusing primarily on single-use plastic packaging with the goal of drastically increasing plastic recycling rates.

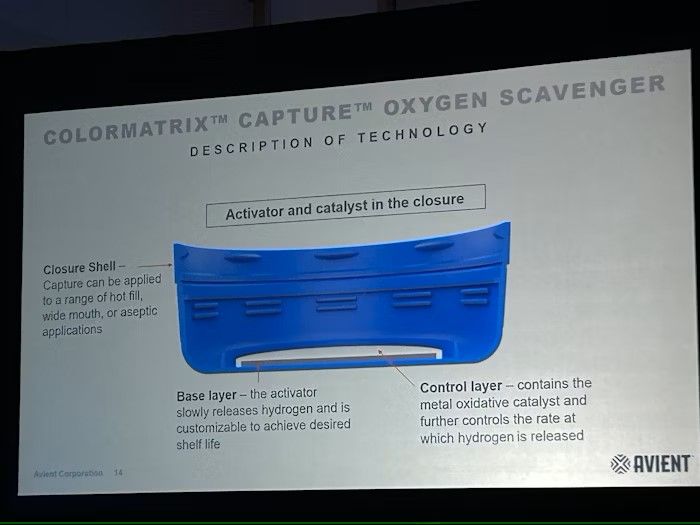

Elvis Cudjoe, Senior R&D Engineer at Avient, showcased the ColorMatrix Capture Oxygen Scavenger technology at The Packaging Conference, a significant step forward in addressing the yellowing issue of PET bottles due to oxygen scavenging additives. This innovation is cleverly incorporated into the bottle cap, ensuring the PET remains fully recyclable.

¿Quiere personalizar su solución de embalaje en tubos o cajas? ¡Deje sus necesidades a continuación y nuestros expertos se comunicarán con usted pronto!